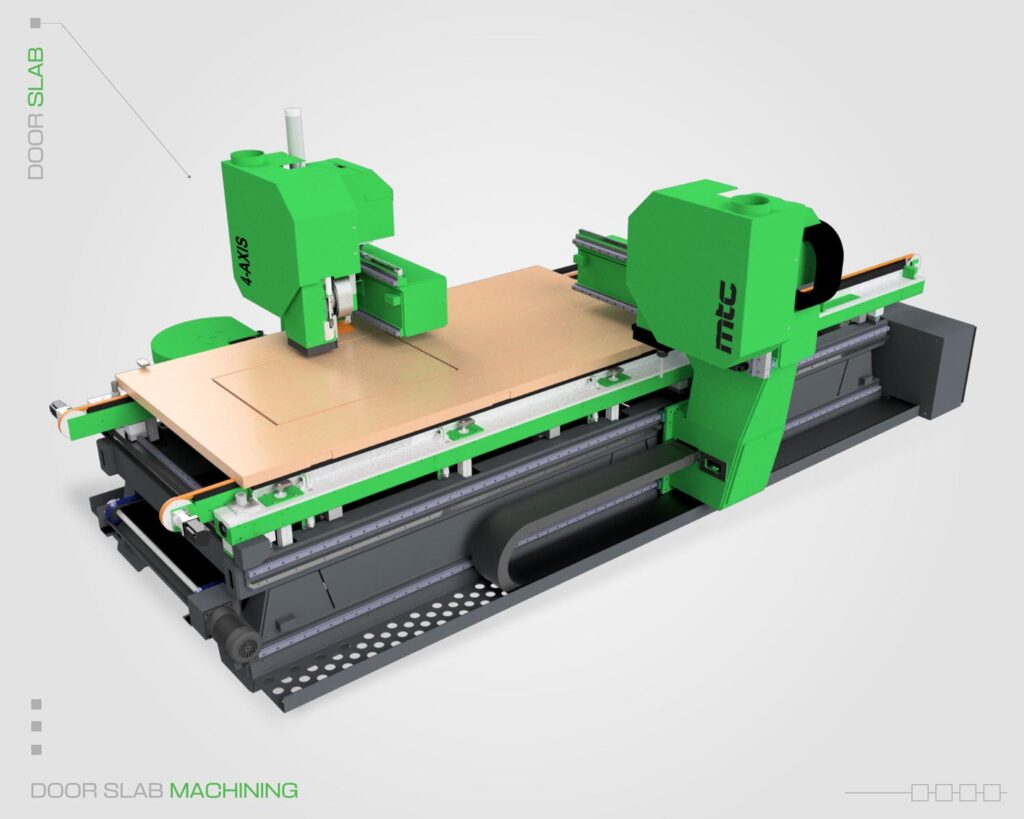

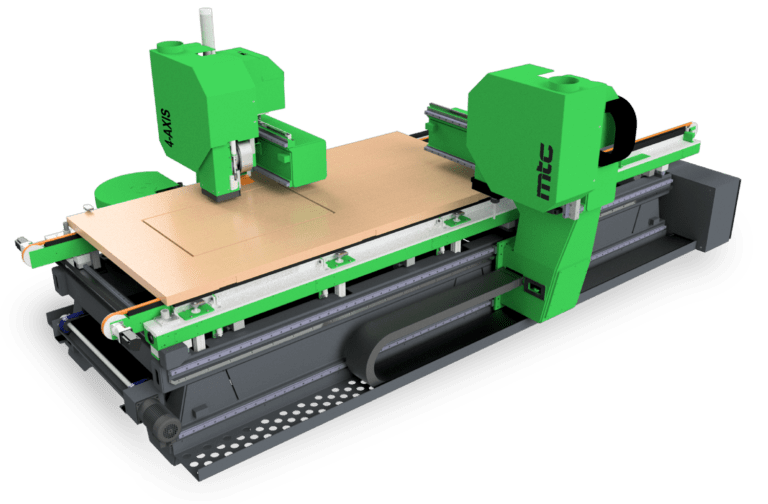

Door Slab

Door Slab Machining

Our system processes wood, steel, and fiberglass doors, handles everything from hinge prep to slab beveling, and more.

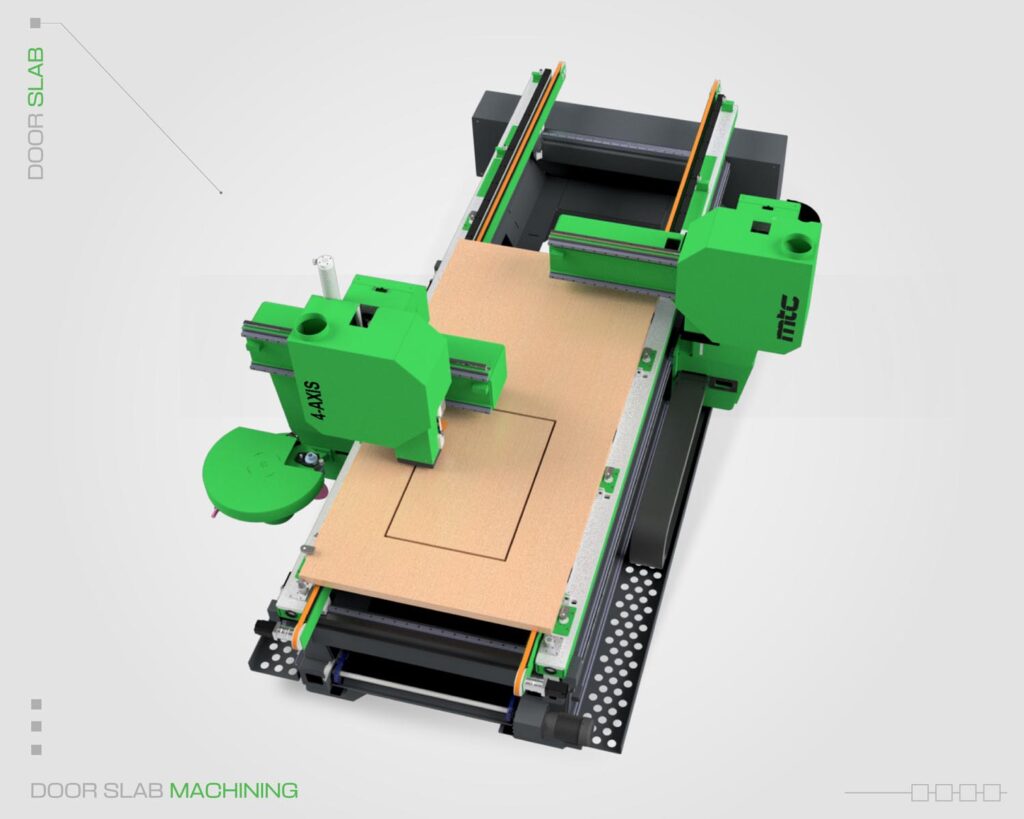

Advanced Door Slab Machining

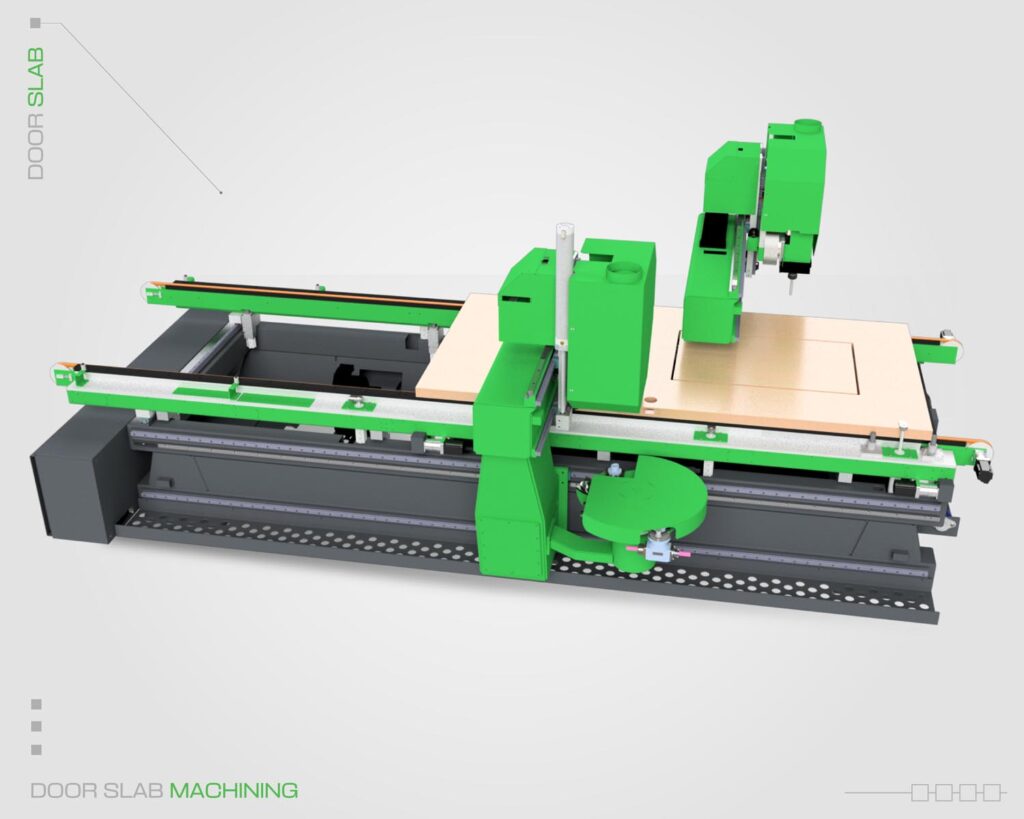

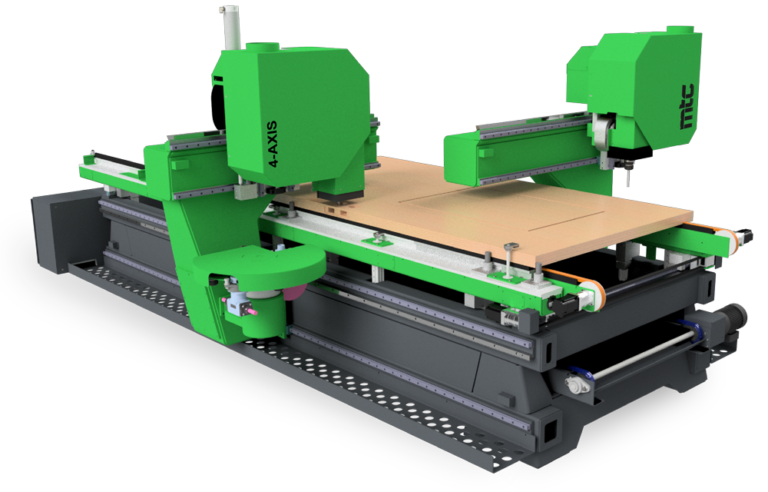

Designed from the ground up for processing assembled and slab doors constructed of wood, steel, and fiberglass. Processing capabilities include Hinge edge prep, Strike edge prep, Deep Mortise pocket, Multi-Point hardware, Face Strike prep, Door-Lite cut-out, Slab Beveling and Squaring. Single or Dual-head configurations offering higher throughput in slabs and side-lites from 10” to 48” wide. Manual loading or upgrade to through-feed conveyance loading.

Technical Details

01.

Standard Features

- Single Machining Head with 13HP routing spindle

- “A” Axis Spindle rotation for machining edge and face features

- Slabs and side-lite panels from 10” to 48” wide

- Slabs lengths up to 96” long

- Mechanical clamping

- Hardware Face reference for accurate feature depths on both edges

- On-Board, Continuous, Long-Term Lubrication bearing technology

02.

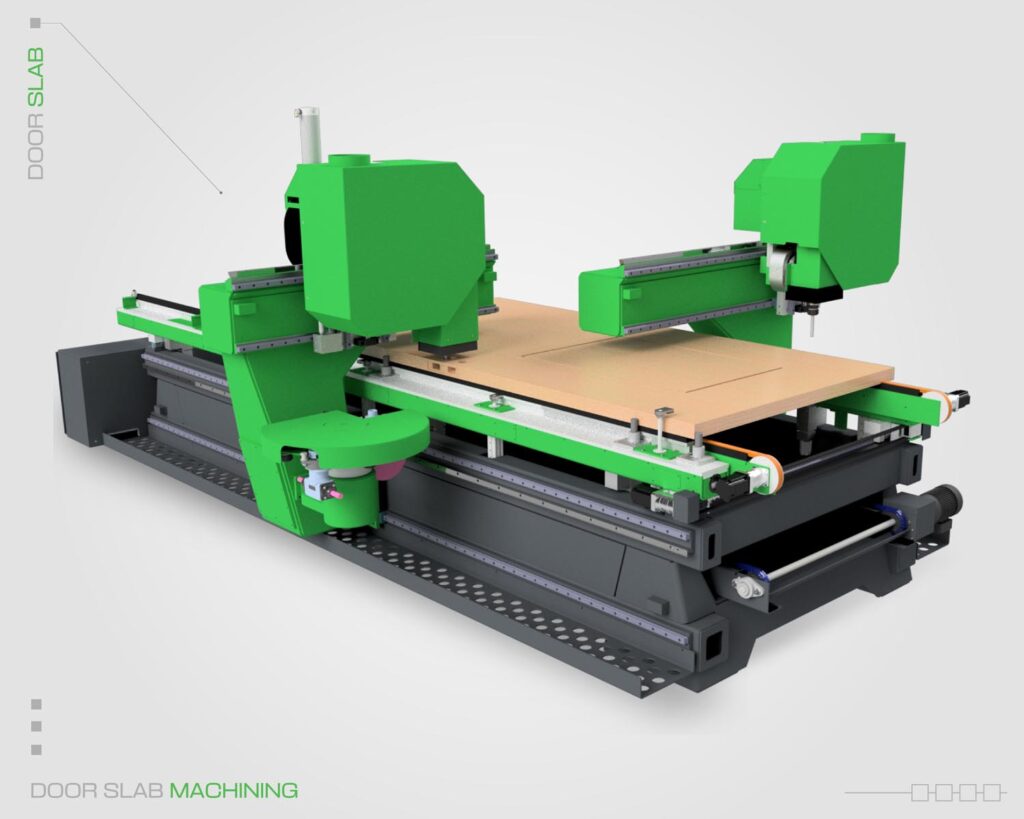

Optional Features

- Dual Head configuration for higher throughput

- Automatic Width Adjustment

- Vacuum Clamping allowing for door squaring, beveling, and euro-groove features

- Automatic Tool Changer

- Chip Conveyance System

- Aggregate for Top and Bottom Edge machining

- Powered Through Feed conveyance system