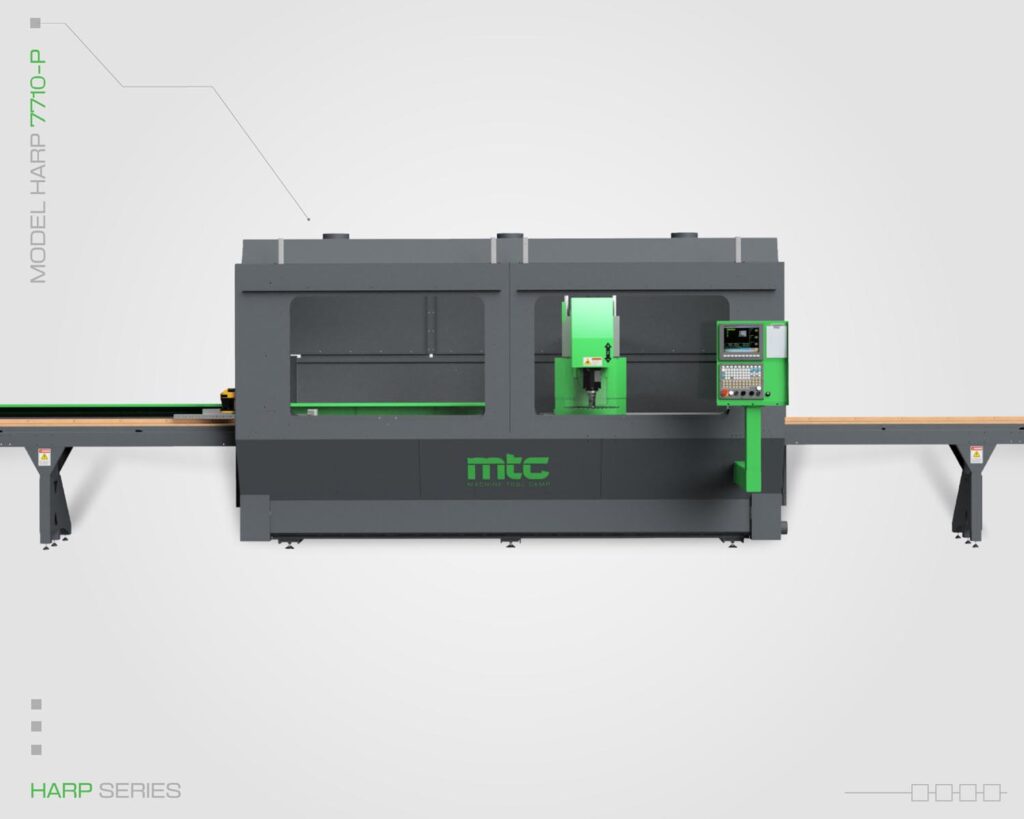

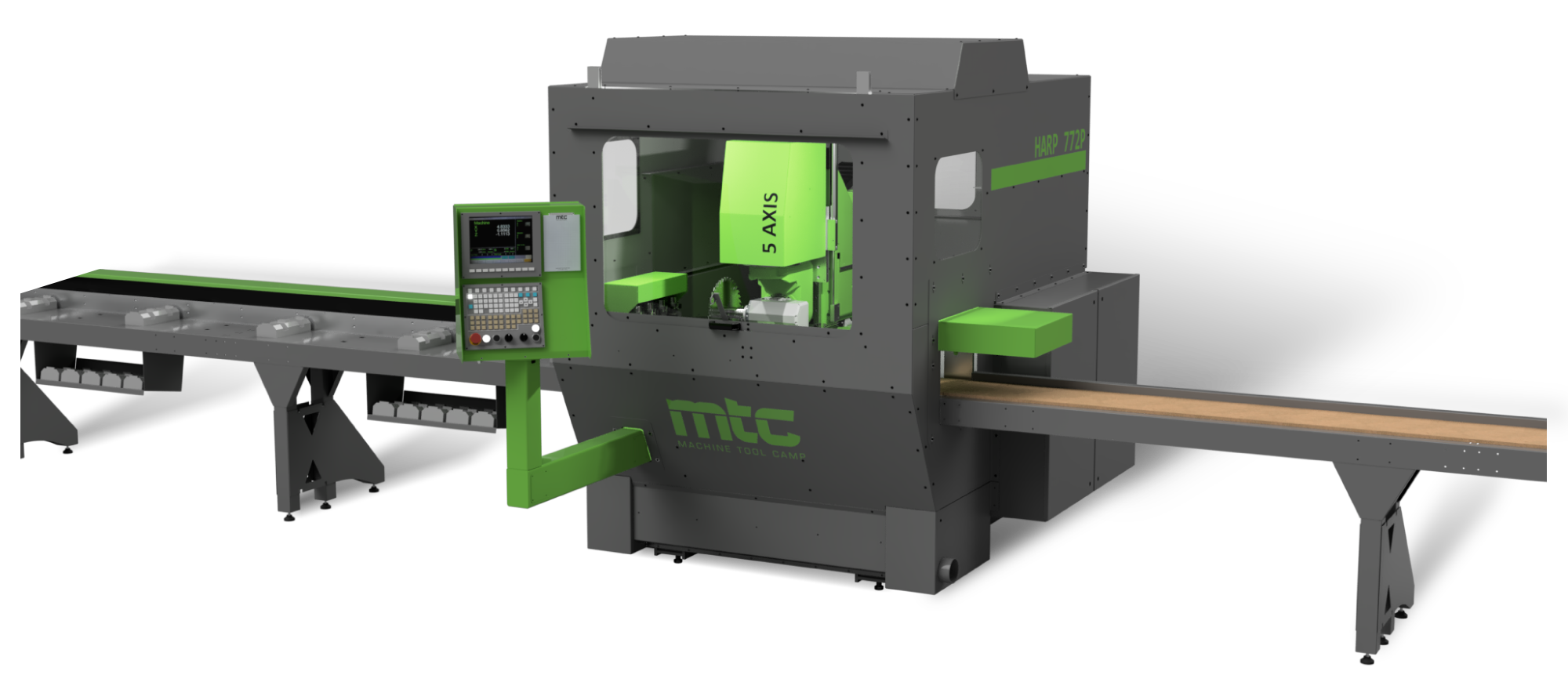

Harp Series

Long & Narrow Parts Machining Center

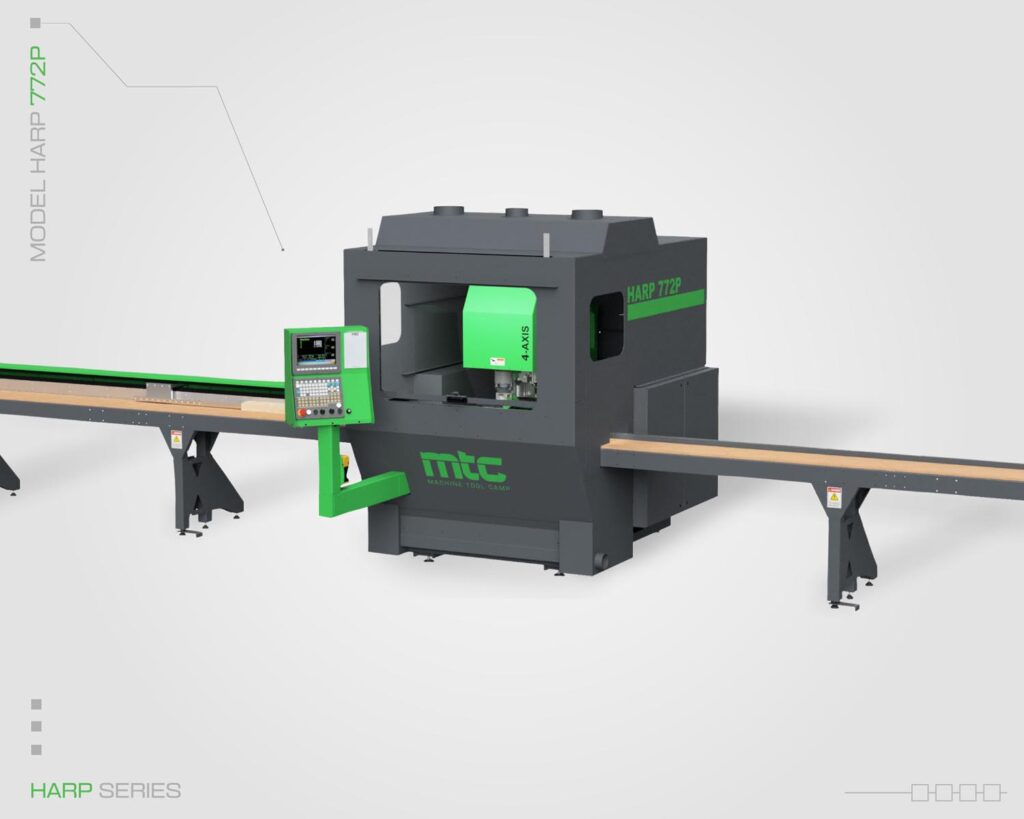

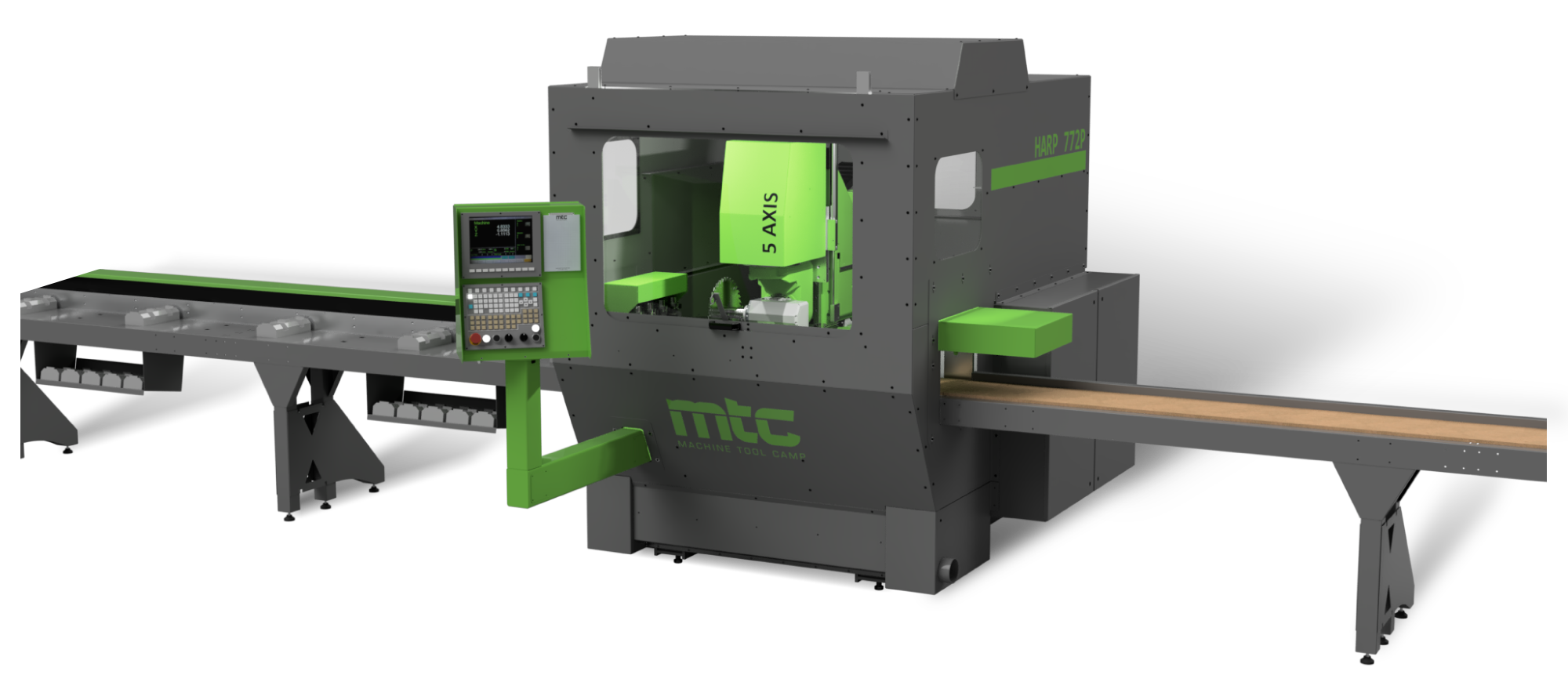

CNC Control System

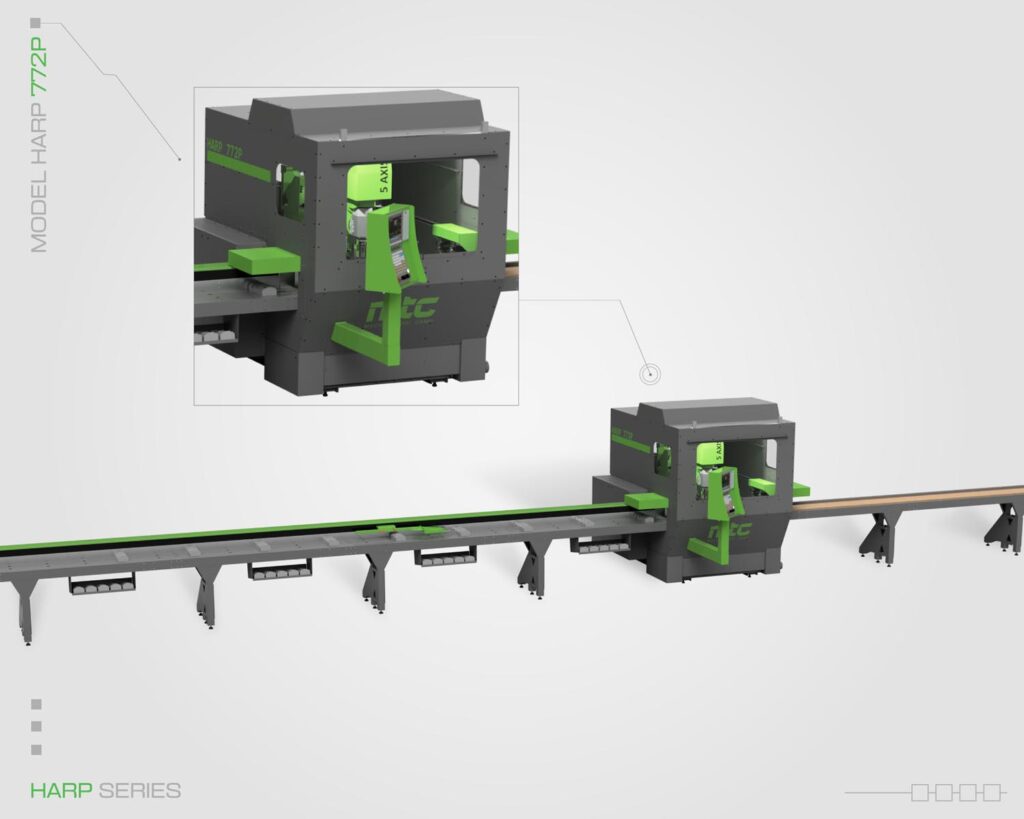

Capable of running up to 4 cutting heads simultaneously

Configurable

Customizable cutting tool options

Expandability

Up to 12-axis system with 4 cutting heads and 8 spindles

Clamping System

Reconfigurable clamping system

CNC Machining Center

for High Aspect Ratio Parts

The HARP series of CNC machines are designed specifically for Long & Narrow part processing. High throughput is achieved with multiple spindles cutting simultaneously via a Multi-Thread CNC Control system. “Push-Feed” configurations as well as “Multi-Head” configurations are key to processing hard-to-hold parts from narrow raw materials including wood, composite, aluminum, plastic and other advanced materials.

CNC Machining Centers

for High Aspect Ratio Parts

Customized with tailored fixtures and spindles, these machines feature up to four independently controlled cutting heads, boosting throughput up to 10x compared to standard CNCs. In the door & window industry, HARP machines craft over 1,600 door jambs in just one 8-hour shift, aided by fully automated load/unload systems.

Technical Details

01.

Available Features

- Parts up to 31’ long

- Tool changer options

- Chip Conveyance Systems

- Mechanical clamping systems

- Through-Feed loading

- Hopper-Feed loading

- Robot loading

- Multi-Thread CNC Control System

- Custom clamping fixtures

- Custom spindle configurations

03.

Optional features

- Single or Multiple Heads

- Routing, Drilling, Sawing, Sanding

- Up to 10+ spindles in cut

- “Push Feed” Single Head configurations

- “Multi-Head” configurations

- Mechanical clamping removes Twist, Crook, Bow

- Hardware Face reference for accurate feature depths

- On-Board, Continuous, Long-Term Lubrication bearing technology