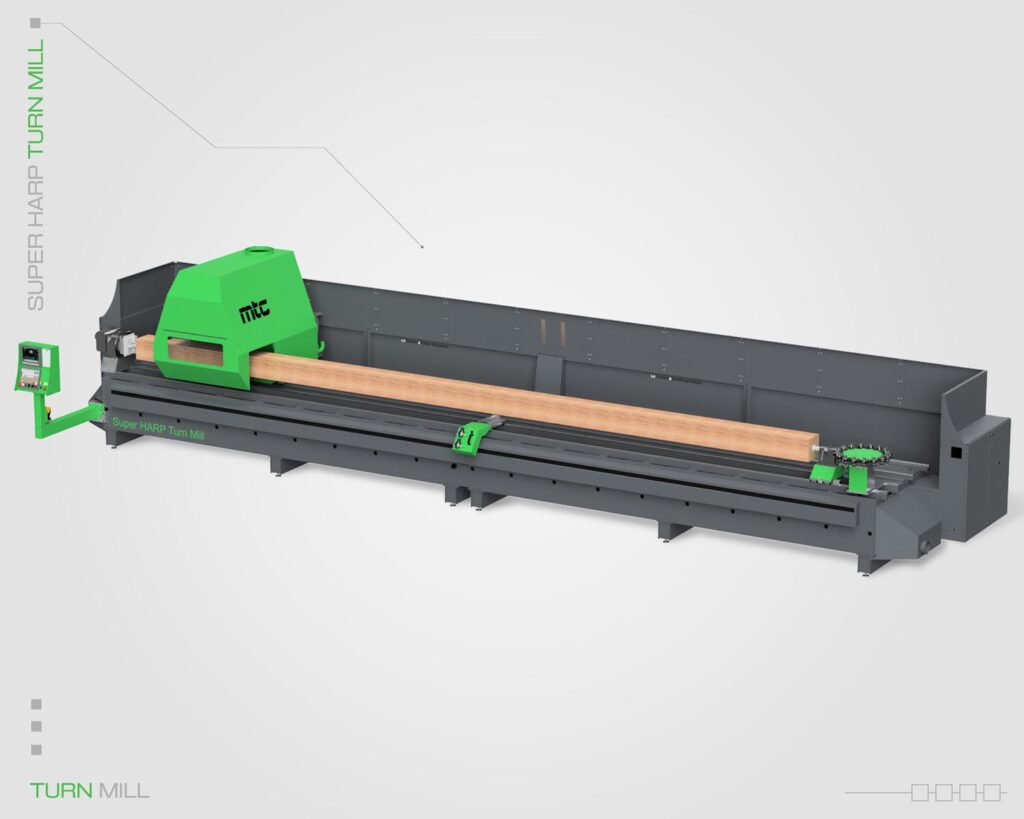

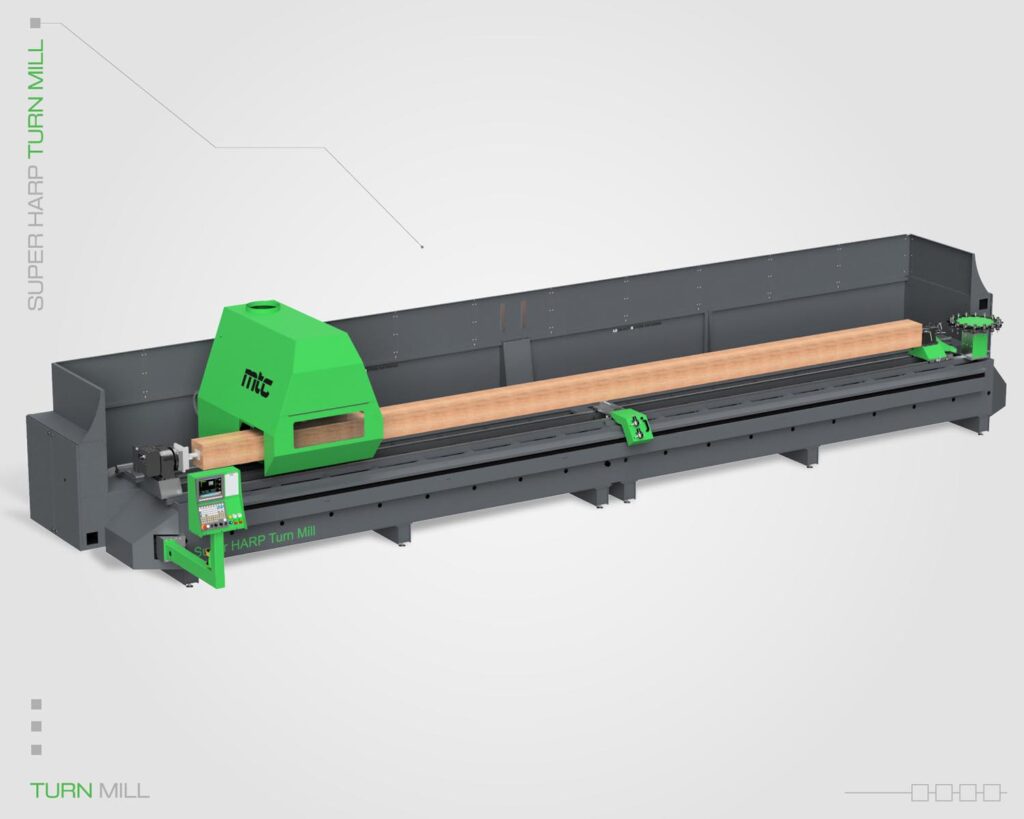

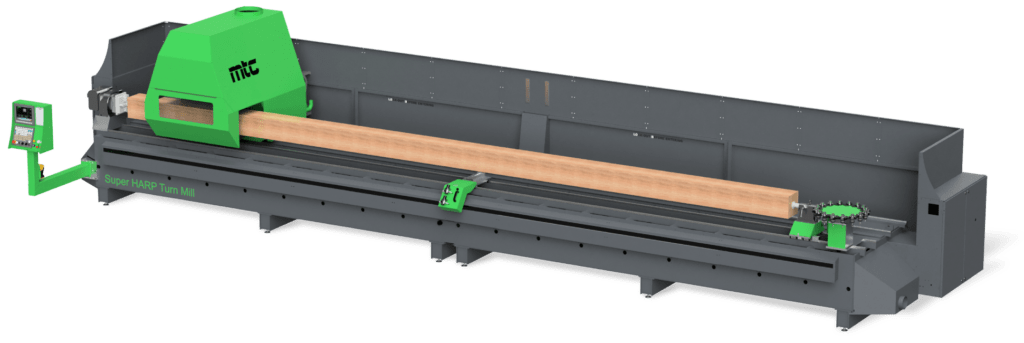

Turn-Mill

LathE & Mill Processing

The Turn Mill crafts parts up to 14″ in diameter (or 10″ square) and 164″ in length, all powered by an industrial controller.

Turn Mill CNC

The Turn Mill allows for continuous and indexed rotation of parts up to 372” long and up to 14“ in diameter. Completing traditional lathe and milling work in one operation, the Turn-Mill utilizes G & M Code programming, and is available with multiple spindle and steady-rest options.

Technical Details

01.

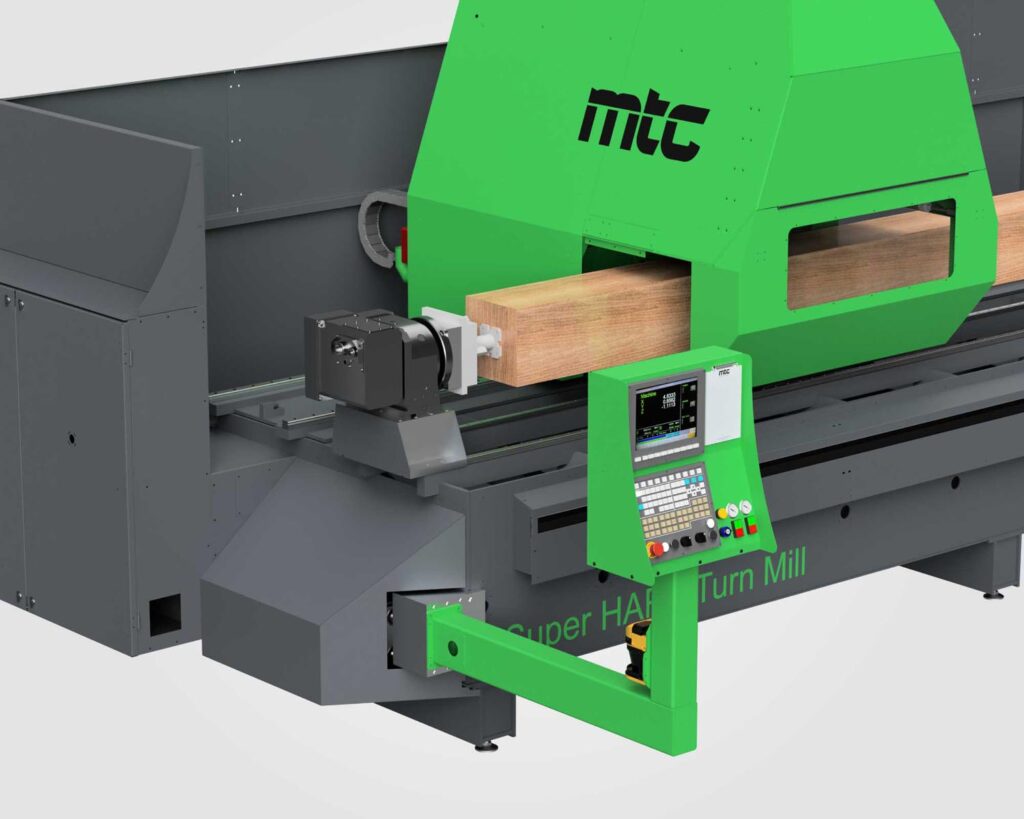

Standard Features

- Fully interpolative X, Y, Z, A axes

- X-axis travel of 168”

- 13.4HP vertical spindle

- 9 pocket automatic tool changer

- Milling mode of operation

- Turning mode of operation

- 3 or 4 Jaw Chuck

- Adjustable Tail Stock

- On-Board continuous, Long-Term Lubrication bearing technology

- High Velocity Dust Collection

- Integrated Chip Shed

02.

Optional Features

- 13-22 Pocket Automatic Tool Changer

- Sag Mitigating Horizontal Spindle

- 15HP, 12” Vertical Moulder Head

- Self-Centering Steady Rest

- Integrated Chip/Chunk Conveyor

- X-Axis Travel up to 372” Long